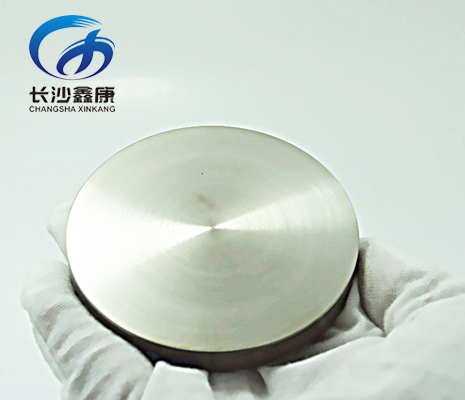

The molybdenum( Mo)sputtering target has the same properties as its raw material. In its pure form, molybdenum is a silvery-grey metal with a Mohs hardness of 5.5, and a standard atomic weight of 95.95 g/mol. It has a melting point of 2,623 °C (4,753 °F); of the naturally occurring elements, only tantalum, osmium, rhenium, tungsten, and carbon have higher melting points.It has one of the lowest coefficients of thermal expansion among commercially used metals.

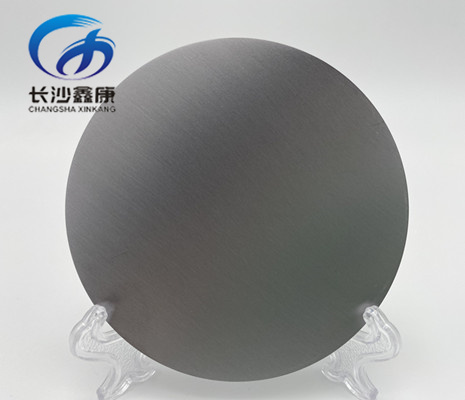

Molybdenum has the advantages of superior electrical and thermal conductivity, small thermal expansion coefficient and strong corrosion resistance. It is mainly used in electric vacuum devices, high temperature furnace heating elements, heat insulation boards and evaporation boats, etc. For molybdenum sputtering target, it's widely used for field of TFT-LCD, thin film solar cells and semiconductor fields

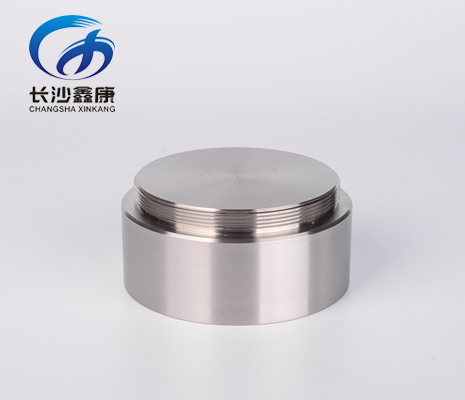

Thanks to our special forming processes, our Molybdenum sputtering targets possess higher density and smaller average particle size, so that you can benefit from a faster process due to higher sputtering speed.

The microstructure can be adjusted by our flexibility production process, to achieve your desired effect. If the grains of the sputtering target are uniformly aligned, the user can benefit from constant erosion rates and homogeneous layers. Following are two micrographs of our molybdenum sputtering target, the average grain size<100μm.

.png)

+86-731-84027969

+86-731-84027969

info@xk-sputteringtarget.com

info@xk-sputteringtarget.com

.png)

.png)

.png)

.png)

.png)

.png)