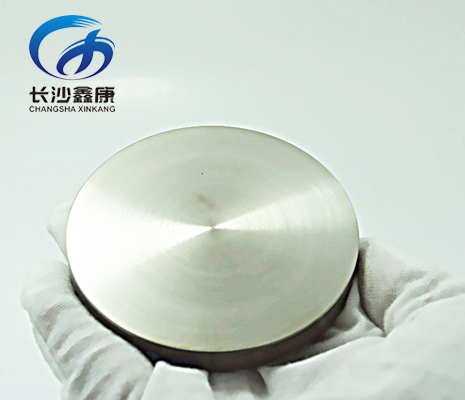

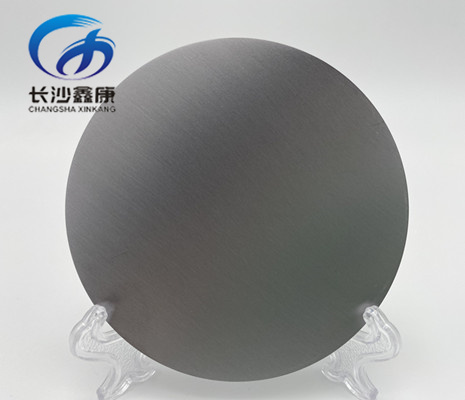

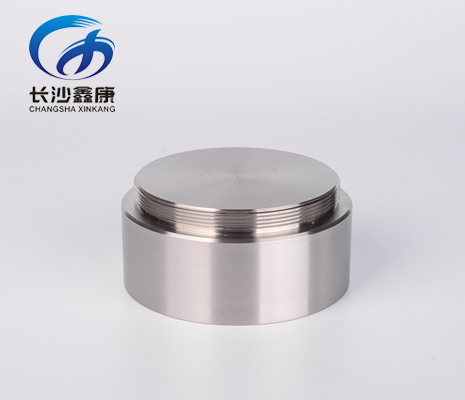

The iron chromium (FeCr) alloy sputtering target is grayish black in colour. We produce iron chromium alloy sputtering target with different iron and chromium content by vacuum induction melting method . In industry, iron chromium is the most important raw material for the production of stainless steel. It is mainly used in the production of stainless steel, ball bearing steel, tool steel, nitrided steel, heat-strength steel, quenched and tempered steel, carburized steel and hydrogen-resistant steel. Chromium plays a decisive role in stainless steel, there is only one element that determines the properties of stainless steel, and that is chromium. Every stainless steel must contain a certain amount of chromium. In the thin film coating industry, researchers have used magnetron sputtering to deposit FeCr alloy coatings in order to replace pure chromium coatings, which can eliminate serious pollution problems, save energy, save chromium resources, and the obtained iron chromium alloy coating is easy to form an amorphous structure, has better performance than single crystal coating, and mainly used in laboratories and automotive industries.

.png)

+86-731-84027969

+86-731-84027969

info@xk-sputteringtarget.com

info@xk-sputteringtarget.com

.png)

.png)

.png)

.png)

.png)

.png)