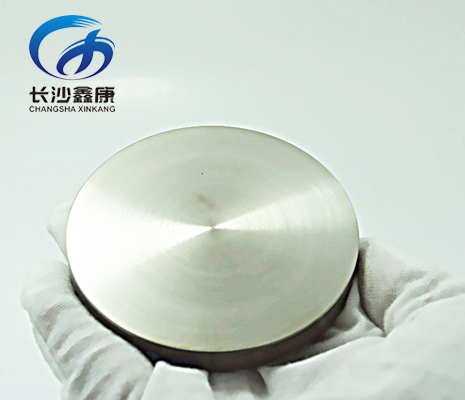

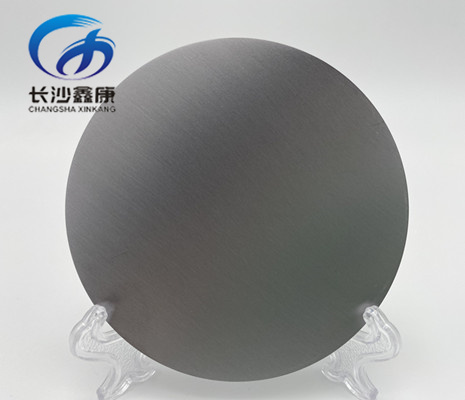

The copper nickel(CuNi) alloy sputtering target is silver white with metallic luster colour. The addition of nickel to pure copper materials can significantly improve strength, corrosion resistance, hardness, electrical resistance and thermoelectricity, and reduce the temperature coefficient of resistivity. As the proportion of nickel content increases, the thermoplasticity is significantly reduced, and the strength and hardness are greatly improved.

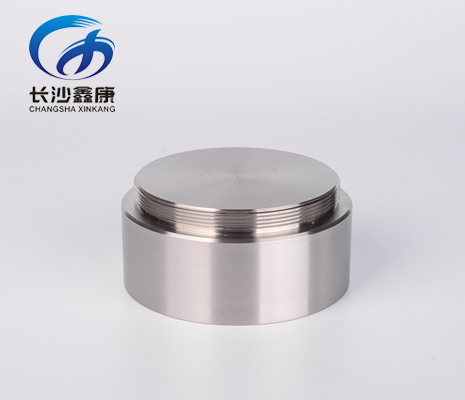

Method for preparing copper nickel alloy sputtering target

The preparation process of copper nickel alloy target is melting the metal raw materials into alloy ingots, and then plastically form the ingots through the forming process to meet customers’ required shape and size;

Application field of copper nickel alloy sputtering target

It has been widely used in semiconductor integrated circuits (VLSI), optical discs, flat panel displays, and surface coating of workpieces.

Uses of copper nickel alloys

It is widely used in shipbuilding, petrochemical industry, electrical appliances, instrumentation, medical machinery, daily necessities, handicrafts and other fields, and it is also an important resistance and thermocouple alloy.

Following is a typically Certificate of analysis for 4N Copper Nickel (CuNi 55/45wt%) sputtering target.

.png)

+86-731-84027969

+86-731-84027969

info@xk-sputteringtarget.com

info@xk-sputteringtarget.com

.png)

.png)

.png)

.png)

.png)

.png)