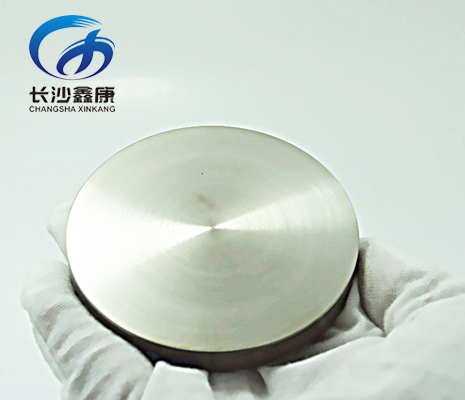

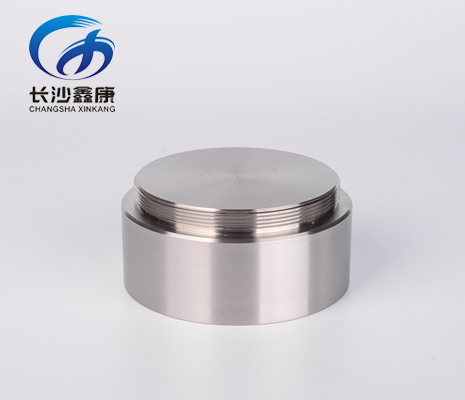

Aluminum Titanium (AlTi) alloy Sputtering Targets are produced by HIP technology, widely used for tool coating and decorative coating.Compared to melting technology, TiAl targets that produced by HIP technology have more uniform micro-inner structure, smaller grain size, and suitable for various magnetron sputtering machines and ion plating machines. End user can obtain constant erosion rates as well as high purity and homogeneous thin film coating during PVD process.

The tools coated by AlTi thin films have higher feed speeds, better cutting performance, longer service life and higher metal removal rates can be achieved without difficulty.

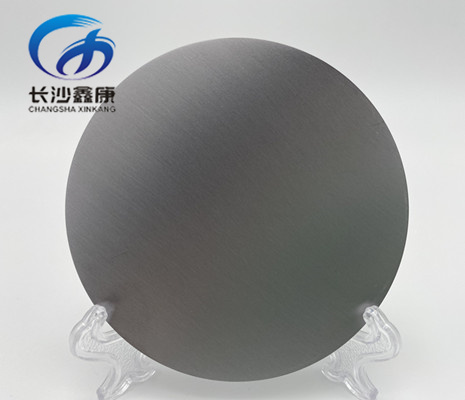

Aluminum Titanium Sputtering Targets and arc cathodes are also used for decorative coating, to obtain golden brown and brownish black color films.End user can obtain good hardness, high brightness, corrosion and oxidation resistant color without discolor for a very long time. Our targets have already been qualified by many end users, including manufacturers of watch, sanitary ware, car mirrors, and etc.

Xinkang produce AlTi25/75at%, AlTi30/70at%, AlTi33/67at%, AlTi40/60at%, AlTi50/50at%, AlTi70/30at% targets and cathodes for decorative and tool coating. The flexibility of our production process allow the microstructure of our coating materials be adjusted to achieve your desired effect. If grains of sputtering target are uniformly aligned, the user can benefit from constant erosion rates and homogeneous layers.

.png)

+86-731-84027969

+86-731-84027969

info@xk-sputteringtarget.com

info@xk-sputteringtarget.com

.png)

.png)

.png)

.png)

.png)

.png)