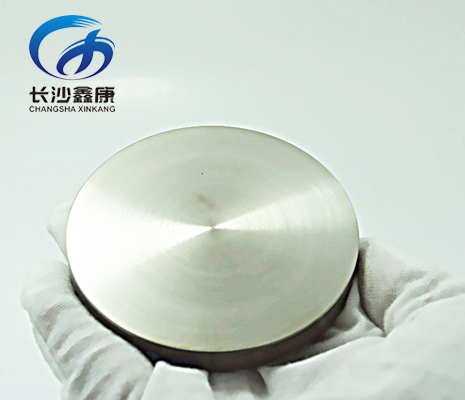

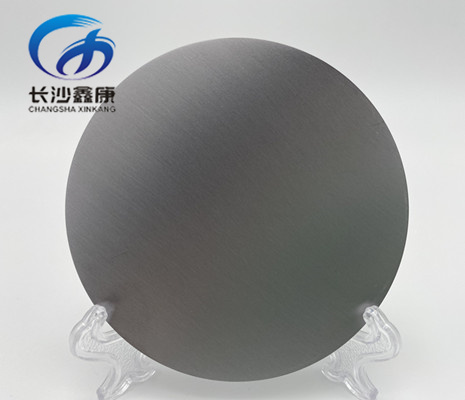

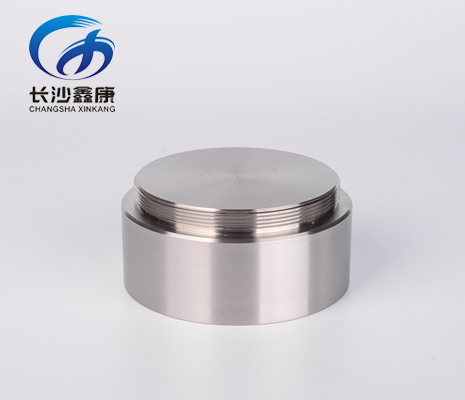

Aluminum sputtering target and preparation method thereof

Aluminum is obtained by extracting Al2O3 from bauxite and electrolyzing it in molten cryolite. The purity is generally above 99%. However, aluminum with such a purity cannot be used as the raw material for the production of aluminum targets. The first and most important requirement is high purity. The high-purity aluminum used in the aluminum target is produced through segregation, three-layer electrolysis or combined zone smelting. The price is more expensive than industrial pure aluminum 99.7 Many, the highest purity in China is about 99.9999% (6N). With high-purity aluminum ingots as raw materials, forging, rolling, and heat treatment of the raw materials can make the grains in the aluminum ingots become smaller and increase the density to meet the requirements of aluminum targets for sputtering. The high-purity aluminum material after deformation is processed by mechanical processing. The aluminum target processing requires high precision and high surface quality, and it can be processed into the target size required by the vacuum coating machine.

.png)

+86-731-84027969

+86-731-84027969

info@xk-sputteringtarget.com

info@xk-sputteringtarget.com

.png)

.png)

.png)

.png)

.png)

.png)