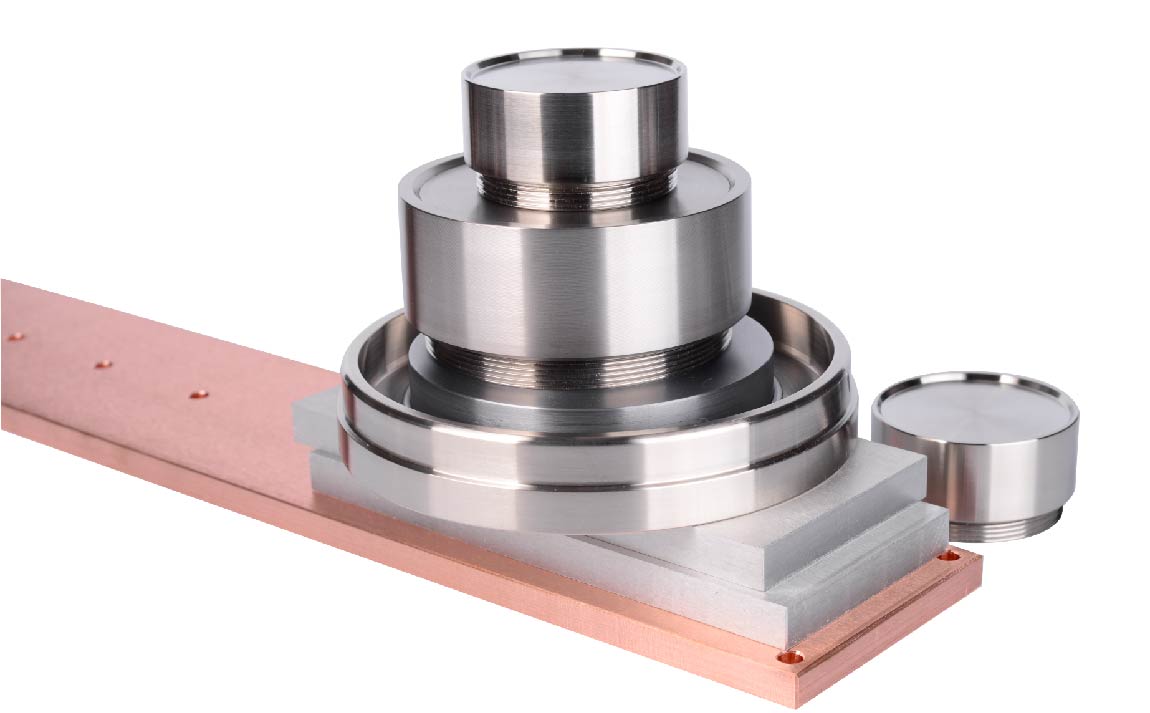

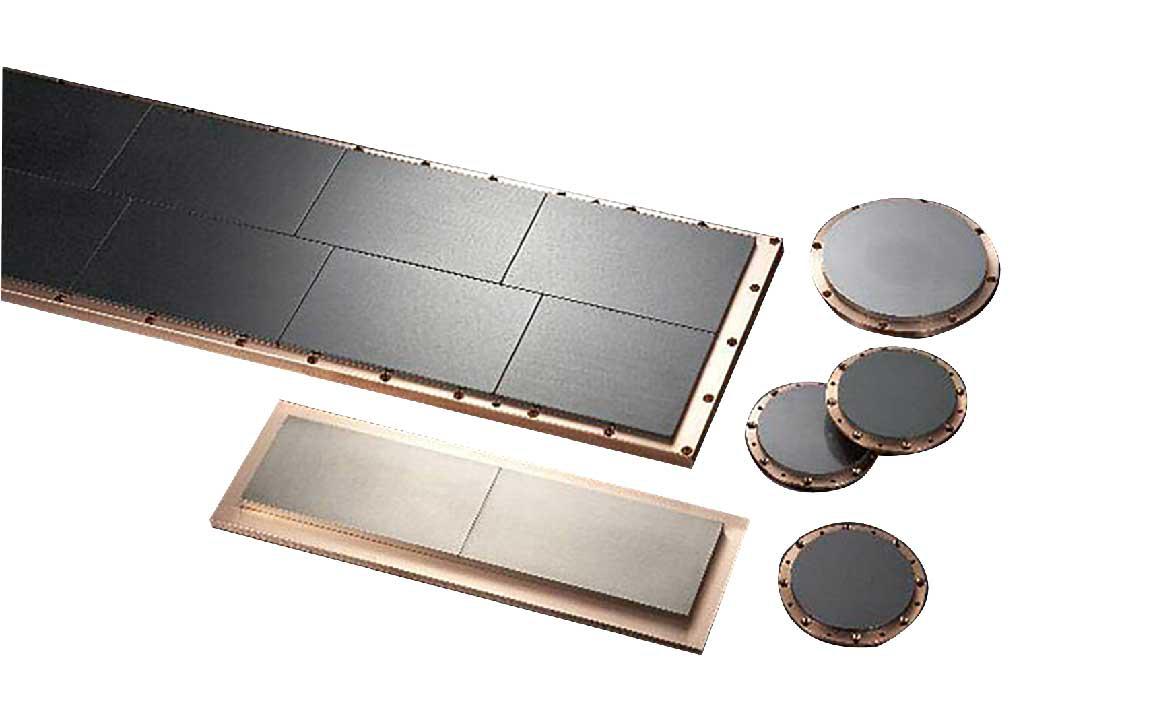

Supplying PVD coating materials one-stop solution

1000+ Target & Evaporation materials for you to choose

Changsha Xinkang Advanced Materials Co., Ltd (Changsha Xinkang) is a worldwide high-tech enterprise in advanced material industry. Relying on the continuous innovation of technology and efficient operation models, we provides customers with high-quality products as well as sincere services

2014

Establishment

52

Trained Employees

3900㎡

Workshop

1000+

Products

Why Choose Us

We Can Not Only Provide You With Excellent Service, Cost-Effective and Good-Quality Products, But Also Customize Products According To Your Needs.

Stable Supply Chain

With a well-established stable supply chain and long-term partnership with suppliers, we better respond to your needs with no delay and secure the materials supply for you.

Strict Quality Control

Trusted by the world's leading PVD coating materials enterprises, famous universities and institutes, Xinkang follows the quality standard ISO 9001 and ISO 14001 in the whole process of PVD coating products.

Fast Lead Time

We can follow up on your schedule and remain quality as a PVD coating materials supplier even if you need it urgently. Regular products are in stock, and customized products are delivered within 2-4 weeks; Enjoy fast production with experienced manufacturers directly.

Full Customer-orientation

We have established 5+ years of partnership with most of our customers, as customer value and satisfaction are always our first thoughts.

One Stop Solution

Xinkang can provide a full range of solutions for PVD coating materials, including sputtering materials, evaporation materials, evaporation sources, as well as various bonding solutions.

One Day Delivery For Standard Materials

One Day Delivery For Standard Materials  Two Weeks Delivery for Mass Production Orders

Two Weeks Delivery for Mass Production Orders Top 10 Sputtering Targets Manufacturers in the USA 2025

Discover the top 10 sputtering targets manufacturers in the USA for 2025. Compare leading suppliers, material capabilities, purity levels, custom alloys, and industry applications across semiconductors, optics, displays, solar, and advanced thin-film technologies.

Environmental Impact of Sputtering Target Materials

Explore the environmental impact of sputtering target materials and discover sustainable practices that reduce waste, energy consumption, and ecological footprint.

Top 5 Sputtering Targets Manufacturers in the UK in 2025

This article is about some sputtering target manufacturers in the UK.

Evaporation Materials Overview

Explore evaporation materials for thin-film deposition, including yttrium-based coatings for semiconductors and solar cells. Learn about applications, challenges, and India’s 2025 market forecast ($100–150M), with solutions from Xinkang Materials.

.png)